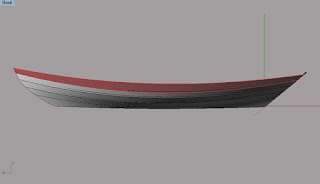

One of the most unique aspects of the St. Lawrence River Skiff (SLRS) is its hull shape which we believe derives from the bark canoes, at least partly. Both hull forms feature a very fine entry and exit to the waterlines. However, on nearly all the St. Lawrence River Skiffs, their after sections are finer than the forward sections.

![]() |

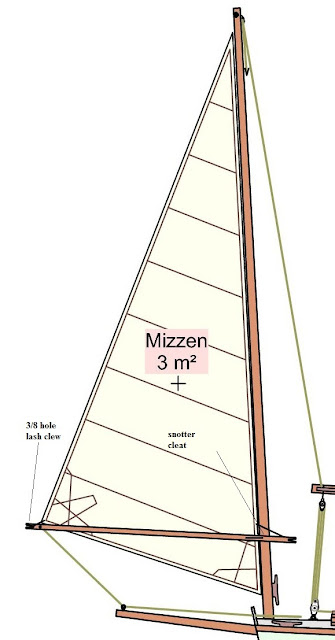

| The bow of an 18-footer, Annie. |

Many rowboats show the opposite, with the aft sections being fuller. The reasoning behind this SLRS hull form regards how the boat trims when under power (oar power, of course). Once the boat is up to speed, the aft part of the hull settles into the water creating a skeg-type effect. A skeg improves tracking of the hull through the water. But by making the hull itself behave as a skeg, we eliminate the extra wetted surface area (WSA in designer speak) that a skeg creates. Any rower knows one tenet of making a rowboat fast: reduce the wetted surface area! This is one reason the SLRS glides along effortlessly with a single stroke of an oar, creating a feeling of flying.

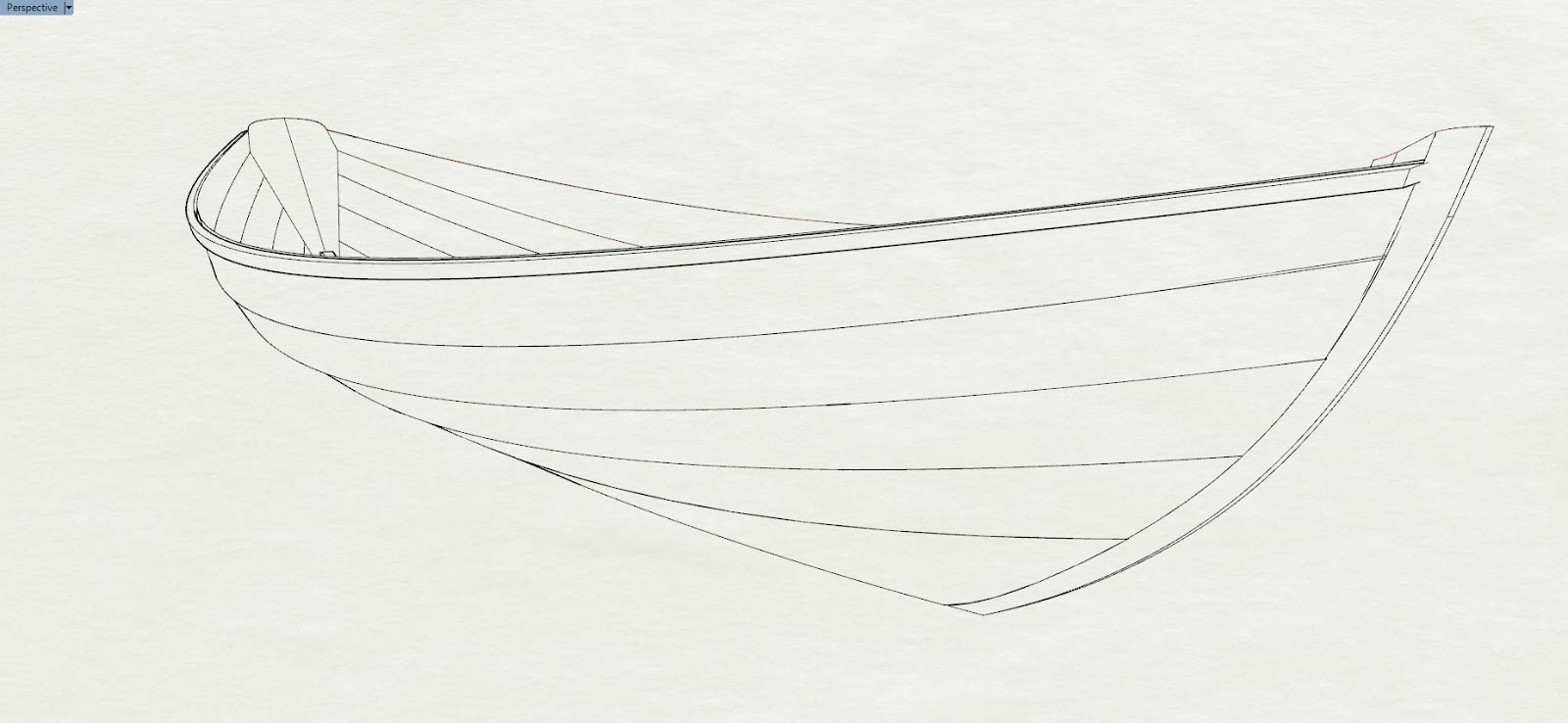

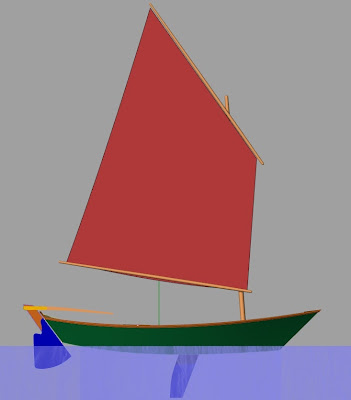

Here is a shot showing the Fry 15 being stripped up. We built the Fry Skiff in 2013 at WoodenBoat using strip-composite construction. A builder by the name of Fry built these circa 1910 in Clayton, NY. The first shot (left) is the bow. The second (right) is the stern view.

![]()

You can see (right) how the strips are fairing into the stern with slight concave curvature even before we've stripped to the designed waterline. The strips are not showing this hollow curvature quite yet in the bow (left). This 15-foot model, shows a pronounced hollow even for a SLRS, partly because the boat is pretty short for a Skiff. (In fact, it is the shortest I'd recommend for fast rowing. I chose the Fry 15-footer because it is going to be the cartopper in my catalog.)

So this is the 'fineness' or 'hollow' in the stern that I am asserting is a classic feature of the SLRS hull form, making the it such a slippery, fast rowboat.

Two other SLRS's that I am working with, the

Bobby at 20 1/2' (which was strip-built in 2012) and

Clotilde at 18', are true double-enders, meaning they are symmetrical. So one end is not finer than the other, but their waterlines still show a strong hollow fore and aft.

Clotilde is unique because its hull is fairly full in the ends compared to the other SLRS, which has me interested because it may be a faster boat and better in a seaway. So I plan to also model this hull and develop mold kits for Clotilde as well.

Bobby mold kits are available.

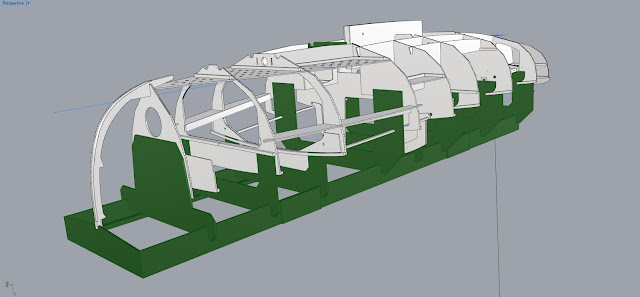

For the first time, the

Fry Skiff is newly updated and ready to cut as a mold kit. She strips up perfectly and produces a hull that is fairer than any hand-lofted set of lines could hope to produce, I dare say. The molds receive a roundovered edge so the soft cedar is not dented. A dado is routed into the molds to make a place for squeeze clamps to hold strips in place. The stems are laminated on fore-aft molds. An alignment batten slots all the molds together in place to ensure squareness and proper spacing. The kit is $750 which includes plans package and the molds.